Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications

|

Polymers for Additive Manufacturing |

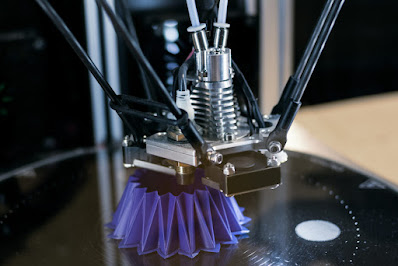

Polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyether ester ketone (PEEK), polyetherimide (ULTEM), and Nylon are examples of thermoplastics or plastics that are manufactured by heating to a semi-liquid condition near the melting point.

Polymers for Additive Manufacturing, also known as additive fabrication, allows for the creation of fully personalized items with a high level of geometrical complexity at a lower cost.

Polymers, in addition to metals and ceramics, have become a highly investigated class of materials for AM applications.

Polymers are the most extensively used class of materials for AM techniques due to their synthetic plasticity and adaptability, as well as the large range of qualities that may be obtained with polymer materials.

The basic concepts of the most relevant polymer AM technologies are discussed in this review, which takes into account the printing technique as well as the benefits and drawbacks.

The unique characteristics, qualities, and limits of currently used polymer systems in several Polymers for Additive Manufacturing technology fields are described and discussed.

Following that, 4D printing is explored, which is the construction of 3D printed structures that may alter over time.

The many shape alterations studied, as well as the polymeric materials and processes under development for 4D printed structures, are briefly described.

Finally, illustrated examples of the main applications are discussed based on the properties of the polymers used in each technology.

3D printing, often known as Polymers for Additive Manufacturing, refers to several cutting-edge technologies for creating three-dimensional objects.

To produce an object, successive layers of material are generated under computer control in additive manufacturing.

These items are made from a digital 3D model or other electronic data sources and can be practically any shape or geometry.

This topic has gotten a lot of interest recently since it opens up new possibilities for polymers in future manufacturing.

Additive manufacturing, rather than 3D printing, maybe a better phrase to use because it encompasses all "additive" processes.

The word "3D printing" has a broader meaning.

Each technology and material caters to a specific market segment.

Resin-based, powder-based, and filament-based materials are the most prevalent polymer AM materials.

Epoxy or methacrylate groups, as well as a photoinitiator, make up resin-based compounds, which solidify when exposed to light or laser.

Comments

Post a Comment